Intelligent, digital and automation technology for Industry 4.0

IO-Link technology is a low-cost communication interface technology that integrates traditional or intelligent sensors and actuators in automation systems. Its design concept is similar to the “USB” interface of industrial automation, which aims to simplify the connection of intelligent sensors and intelligent devices on the factory floor, and it is a communication interface independent of the fieldbus, which can realize the mixed operation of traditional sensors and intelligent sensors without serial communication configuration or network addressing. It is a fieldbus-independent communication interface, which can realize the mixed operation of traditional sensors and smart sensors without serial communication configuration or network addressing, greatly simplifying the connection and integration of devices.

IO-Link sensor solution is one of the important technical wood means to realize equipment interconnection, cooperative work and intelligent production under Industry 4.0. The IO-Link sensor developed by Osun Electronics has many advantages over traditional sensors, providing powerful data transmission and processing capabilities, remote configuration and diagnostic capabilities, compatibility and flexible scalability, etc., which provides strong support for the intelligent, digital and automation technologies of Industry 4.0.

Standardized interfaces simplify installation and maintenance and reduce operating costs.

Unified protocols reduce cable types and lower the risk of failure.

Capable of transmitting a wider range of data types, including switching signals, analog values, pulse signals, etc., to provide more monitoring and control functions in the production process.

Real-time monitoring of equipment status to optimize production processes.

Supports remote parameter setting and diagnosis from PC, which greatly saves time in equipment operation, reduces failure costs, and improves the convenience of debugging.

IO-Link sensors have a high degree of integration and are compatible with existing automation systems.

Easy connection with M12 connectors to avoid wiring errors; standard industrial cables to reduce the number of cable types; one cable directly to the PLC, IP69K protection level, worry-free use in the field.

All parameters of the connected sensors will be saved in the master station. When the same sensor is replaced, the parameters are automatically written to the new sensor.

The 24V signal sends digital signals directly without conversion, no signal loss; insensitive to external influences, ensuring data accuracy; industry standard cable transmission, no need for expensive equipment.

Adapts to various fieldbus and control systems, such as PROFINET, EtherNet/IP or AS-i; Simplifies PLC programming, connects actuators, and creates a streamlined factory architecture.

Easily adjust IO-Link device parameters with the help of related software, speeding up adjustments and reducing downtime; Remote locking of sensors through software prevents parameters from being changed and ensures system stability; Use the software to save device settings and create setup scenarios for efficient management.

IO-Link enables simultaneous transmission of process and maintenance data to improve maintenance efficiency; non-periodic retrieval of diagnostic data, including minimum and maximum values, disconnected or short-circuited, etc., realizing condition-based maintenance; diagnostic data can also be accessed during operation to ensure continuous and stable operation of the equipment.

IO-Link flow sensors can integrate multi-parameter measurements, including flow rate, total flow, and temperature, which are digitally transmitted via standard 3-wire cable. This not only reduces configuration, installation and storage costs for replacement sensors, but also increases the accuracy and efficiency of process control.

As a key technology in the field of industrial automation, IO-Link occupies an important position in the industrial interconnection network. It serves as a communication bridge between controllers and field devices such as sensors and actuators, realizing real-time data exchange and intelligent management.

Through IO-Link, field devices can provide rich process data, diagnostic information and equipment status to the control system, and at the same time accept instructions and parameter settings from the control system, thus improving the level of intelligence, flexibility and adjustability of the industrial automation system. This type of communication greatly promotes the development of industrial interconnection network and makes the production process more intelligent, efficient and flexible.

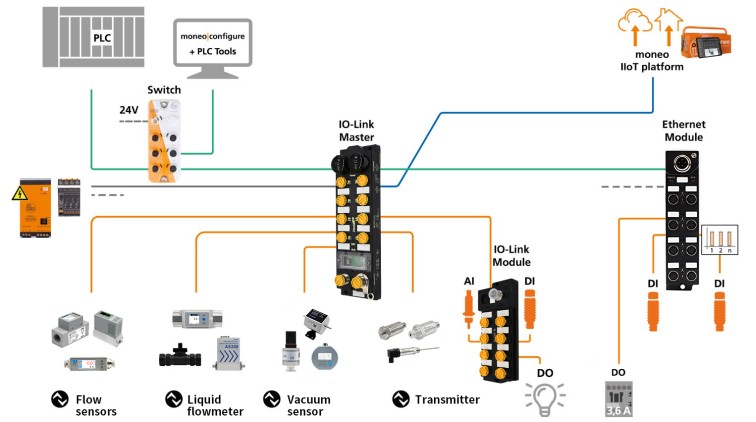

The IO-Link system consists of three core components that work together to realize efficient communication between devices.

As the “brain” of the system, the IO-Link Master is responsible for seamlessly connecting IO-Link devices to a Programmable Logic Controller (PLC) or other control system. Each master is equipped with a dedicated IO-Link interface to ensure smooth communication with the devices.

These devices are the “touch points” of the system and include sensors, actuators, RFID readers, I/O modules, valves, and more. They are connected to the IO-Link master via the M12's four- or five-pin connector to ensure accurate data transfer.

As the “blood vessels” of the system, IO-Link cables are responsible for connecting the IO-Link master to the devices. These cables are usually 3-core or 5-core unshielded wires, including data lines, power lines and ground lines, to ensure that the whole system operates stably and reliably.

All three are indispensable and together form the infrastructure of the IO-Link system.